AI in Manufacturing: Benefits, Use Cases, and What’s Next

Artificial intelligence has the potential to transform entire industries, and manufacturing is no exception. Thanks to advances in data analytics, we now have a strong foundation for adopting AI-based technologies, which can use that data in remarkable ways.

These solutions combine data from sensors, machines, and people to help manufacturers become more data-driven when optimizing production and maintenance processes, improving product quality, and answering the personalization needs of the end customer.

According to Accenture, the manufacturing industry stands to gain $3.78 trillion from AI by 2035.

In this article, we will explain:

- how AI is used in manufacturing

- what are the benefits of AI in manufacturing

- what are some of the use cases of AI in manufacturing

- what’s next for AI in manufacturing

How AI Is Used in Manufacturing

AI in manufacturing refers to using data in combination with machine learning and deep learning algorithms to automate tasks and make manufacturing operations faster, better, and more precise.

Manufacturers can use AI solutions in every step of the production process, from sourcing raw materials and components to optimizing production and even post-sales activities.

For instance, manufacturers now use AI to design products more efficiently, creating prototypes or testing production scenarios virtually before anything is built.

In addition, AI can help by recommending the best suppliers based on pricing, delivery times, or quality. This use case ensures manufacturers get the right materials at the right time, which is crucial for keeping production on track.

AI also plays an important role in optimizing customer service within the manufacturing sector. By using chatbots and virtual assistants, manufacturers can now provide support 24/7.

B2B customers are increasingly looking not only to solve issues, but fully manage their experience through digital self-service platforms. In many of these cases, AI solutions can be embedded within self-service portals to provide a better experience and automate repetitive tasks.

From start to finish, AI helps manufacturers work more efficiently, make better decisions, and deliver higher-quality products to their customers.

Benefits of AI in Manufacturing

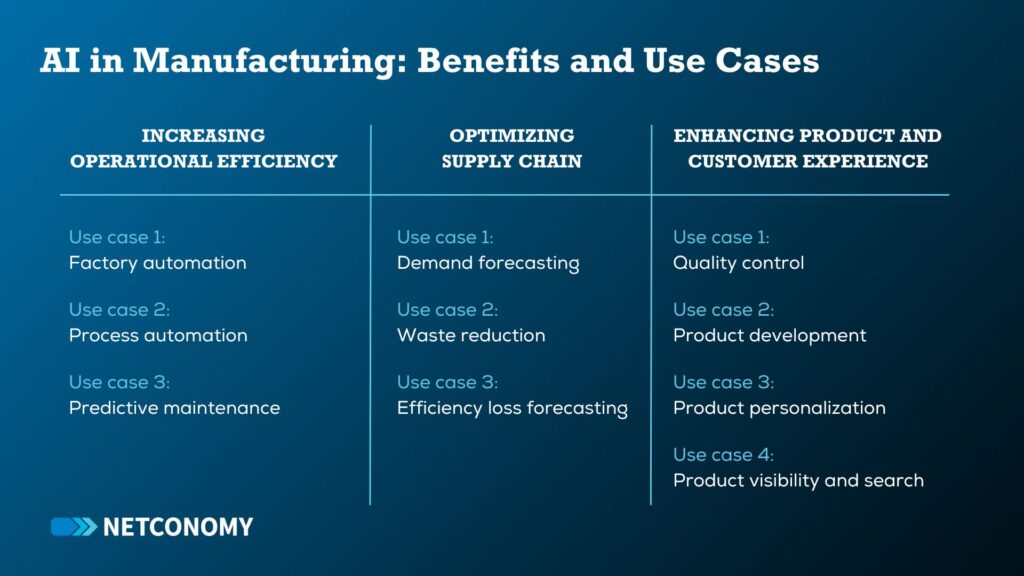

The three main benefits of using AI in manufacturing are:

- increasing operational efficiency

- optimizing the supply chain

- improving the product and customer experience

Combined with the high number of AI use cases in the manufacturing process, it’s not surprising that a 2024 survey by the Manufacturing Leadership Council shows that 78% of manufacturers indicate that their AI initiatives are part of the company’s overall digital transformation strategy.

These benefits have become even more crucial today, as manufacturing leaders face an uncertain economic outlook, tougher competition, and a bigger focus on differentiation through services.

Next, we’ll talk about how each of these three benefits can help your company lower costs, optimize processes, and improve your market positioning.

Increasing Operational Efficiency

The increase in operational efficiency is one of the main benefits AI brings to manufacturers. By minimizing or automating repetitive tasks, AI solutions allow employees to focus on high-value activities instead. This means people spend less time and resources on low-value tasks, increasing overall speed and productivity.

Likewise, by implementing machine learning capabilities and predictive analytics, manufacturers can predict failures and proactively address potential issues. This results in a more agile manufacturing process that minimizes downtime and removes dependencies.

Optimizing the Supply Chain

By augmenting data analytics with machine learning, manufacturers can foresee market developments and business risks better than ever.

Not limited to just internal data, they can also analyze external factors to model hypothetical outcomes based on different scenarios.

This precision applies to everything from demand forecasting to efficiency loss. It allows manufacturers to optimize every link of the supply chain – making it more resilient and customer-centric.

Improving the Product and Customer Experience

Today, AI is the critical ingredient for improving customer experience across industries – and manufacturing is no exception.

By combining manufacturing data with signals from the market and running them through machine learning algorithms, manufacturing leaders can get a better understanding of what their customers need and want. They can then customize and personalize their products to match the customer’s preferences.

However, customer experience goes far beyond the product, and AI is the perfect partner to help every step of the way. Thanks to predictive maintenance and superior quality control, AI supports a smooth customer experience with minimal failures or interruptions. And with continuous customer feedback, machine learning models can learn and continuously refine and improve the overall experience.

AI in Manufacturing Use Cases

As we mentioned, there are many different applications of AI within manufacturing. So, you might be confused about where to start.

That’s why we’ve grouped the different use cases based on which benefits they feed into. This grouping will help you pick the best option for your business context.

1. Factory Automation

Factory operators play a major role in the smooth running of the factory – no matter how advanced the system is. These experts rely on their knowledge and experience to manually adjust the equipment or material and troubleshoot unexpected issues.

Their work is crucial – but also prone to human error. That’s why factory automation is used to optimize the manufacturing process within a facility.

By embedding AI capabilities into factory machines and equipment, manufacturers can benefit from automation, which allows them to optimize the overall production process.

2. Product Development

AI has enormous potential when it comes to product development – and this is especially true for the manufacturing industry.

By quickly running thousands of simulations, generative AI solutions can transform various stages of the product development process, from ideating and prototyping to product testing.

Companies can also create detailed virtual environments that mimic real-world conditions. This enables manufacturers to test the performance, durability, and functionality of their products without the expense and time commitment of physical trials.

For example, automotive companies can use AI to simulate crash tests – optimizing vehicle safety designs before building a single prototype. Going forward, we can expect generative AI to become a pivotal tool for achieving both innovation and efficiency in manufacturing.

3. Digital Self-Service

Digital self-service portals are transforming how B2B companies interact with customers by streamlining processes and empowering users with greater autonomy.

These portals go beyond basic transactions, offering a comprehensive platform for managing orders, tracking deliveries, and accessing personalized product recommendations. By centralizing these tools, businesses can reduce manual effort, improve accuracy, and create a seamless user experience that drives customer satisfaction.

With AI-powered features, digital self-service portals enhance efficiency by automating key tasks like resource allocation, order scheduling, and process optimization. They leverage real-time data to provide actionable insights, enabling businesses to meet demand, improve workflows, and proactively address customer needs – all in one intuitive platform.

4. Predictive Maintenance

Predictive maintenance solutions use sensors to monitor equipment and predict possible failures before they happen. But despite its familiarity, there’s still plenty of room for improvement in this area.

With the adoption of AI, manufacturers can analyze data points that would be impossible for humans to process manually. For example, AI systems can monitor the vibrations of conveyor belt motors and detect subtle changes that indicate wear and tear. By alerting operators to schedule repairs before equipment fails, unplanned downtime is avoided.

AgenticAI takes this a step further by actively making decisions based on the data it interprets – like ordering a replacement part on its own.

Through this proactive approach, manufacturers can minimize production interruptions, enhance efficiency, and significantly reduce overall maintenance costs. McKinsey & Company reports that AI-driven predictive maintenance can boost equipment availability by 20%, cut inspection costs by 25%, and reduce maintenance fees by 10%.

5. Demand Forecasting

AI empowers manufacturers to analyze vast volumes of data like never before. AI algorithms combine historical sales data with external factors such as weather conditions, market trends, and economic indicators to make highly accurate demand forecasts.

The forecasts can also be done on a granular level, helping organizations optimize for specific products and locations. In addition, real-time data from various sources allows manufacturers to quickly adapt and respond to changes in demand.

Furthermore, AI algorithms quickly provide simulations of numerous scenarios to help manufacturers make data-driven decisions about demand management.

6. Waste Reduction

It is not surprising that manufacturing is one of the biggest waste-producing industries. Reasons for that vary from inefficient planning to defective products caused by human error.

With machine vision, manufacturers can detect defective materials or components before they go into production and optimize their quality control system.

But even beyond product quality and waste reduction – AI plays a significant role in creating a more sustainable manufacturing industry. Companies can now introduce AI-powered waste sorting systems that are more efficient than any human could be.

Since their efficiency increases as they continue to learn, after enough time, these systems can recognize and cluster hundreds or even thousands of waste types.

7. Efficiency Loss Forecasting

Resource planning, human labor, production process – you name it – when it comes to achieving business goals, it is all about optimization.

AI algorithms can analyze historical data from a range of sources to understand where efficiencies happen and provide accurate forecasting on future deviations.

Moreover, these systems can combine historical data with external factors to identify the root cause of the deviation, such as equipment malfunctions, suboptimal workflows, or supply chain issues.

This ability also helps organizations streamline processes and reduce downtime in the long run.

8. Quality Control

Manufacturers today have an opportunity to fully automate their quality control process. As a result, they minimize the risk of faulty products entering the market and prevent the drop in quality in the first place.

AI systems continuously monitor and analyze data from the production line to provide alerts when they detect quality issues. They also offer insights and recommendations to ensure continuous improvements in quality control.

With agentic AI, it’s now also possible to take it one step further and create an autonomous quality control system that can adjust production parameters in real-time to maintain consistent product quality.

One of the biggest benefits of AI-based systems is their ability to learn over time. By combining data from various resources and considering certain deviations, AI models can identify potential quality issues and provide forecasts.

9. Product Personalization

Similar to retail, AI plays a major role in product personalization for manufacturing. Customers want customized products, and manufacturers must adapt to stay competitive.

AI and ML technologies analyze massive amounts of data from the market to predict preferences that influence product designs. For example, generative AI can be used to create personalized car parts, such as custom dashboards or steering wheels, by analyzing customer preferences in real-time.

These technologies are essential for the concept of mass customization, allowing manufacturers to adapt production lines to meet individual customer needs and produce unique products while maintaining efficiency.

10. Product Visibility and Search

AI significantly contributes to enhancing product visibility and searchability by generating high-quality product data.

The data is pulled from various sources such as customer feedback, online reviews, market trends, and real-time sales data. AI algorithms analyze this data to produce structured and accurate product information, facilitating efficient product searches.

By tagging and categorizing products based on their features, AI simplifies the search process, leading to quicker and more accurate results.

This not only reduces the time taken for customers to find the right products but also improves the overall customer experience by making it more personalized and convenient.

11. Customer Service Automation

Undoubtedly, AI also has a massive impact on customer service operations. With genAI-powered customer service agents, manufacturers can provide round-the-clock customer support without overloading their customer service teams.

AI-enabled chatbots are available 24/7 to answer questions, provide product information, and even handle returns or complaints. This not only improves efficiency but also enhances the overall customer experience by providing personalized and timely assistance.

AI can also analyze customer feedback and sentiment to identify areas for improvement in products or processes, helping manufacturers continuously improve their offerings. By automating these repetitive tasks, AI frees up time for employees to focus on more complex and critical tasks that require human intelligence.

Overall, incorporating AI empowers manufacturers to deliver intelligent customer service that meets the ever-changing expectations of modern consumers.

What’s Next for AI in Manufacturing

New technologies have always been the driver of innovation in manufacturing, and today, AI is playing the main role. As we look ahead to 2025, a key shift will be the perspective of AI as a strategic partner rather than just a tool.

Thanks to innovations such as agentic AI, manufacturers are starting to see AI as a collaborator, enhancing human skills and leadership instead of simply automating tasks. These solutions will soon be able to react and make autonomous decisions, saving you precious time and costs along the way.

This shift highlights the potential for AI to work alongside people, driving innovation and strategic decision-making.

How to Get Started with AI in Manufacturing

When working with customers on their first AI projects, we always start with three crucial questions:

- Do you have an ‘AI strategy’ or another documented way of implementing AI in your company? To be clear, this doesn’t need to be a complex 30-page document. It can be as simple as you need it to be, as long as it shows how using AI fits into your overall business goals.

- Is your data foundation robust enough to support advanced AI solutions?

Nearly 70% of manufacturers have identified data-related challenges – such as poor data quality, lack of contextualization, and validation issues – as major obstacles to implementing AI You need to be able to solve these before getting any value from AI. - How will we track and evaluate the ROI of AI initiatives?

Manufacturers increasingly recognize that AI investments must deliver measurable value. Instead of rushing to adopt the latest innovations, you should focus on use cases that align with your business goals and offer tangible benefits.

By making sure these basics are covered, you increase your chances of success by taking full advantage of the AI solution you’ve chosen.

At NETCONOMY, we’re committed to helping manufacturers unlock the full potential of AI. By focusing on strategic, data-driven solutions, we’re working with our customers to develop AI-powered innovations that drive real business value.

Whether you are uncertain about your AI strategy or already have an AI-powered solution in mind – we are happy to discuss the next steps with your team. Get in touch and let’s chat!

Authors and Contributors

Nenad Pantelic | Data Science Consultant